In the dynamic world of manufacturing, staying ahead of the competition means embracing cutting-edge technologies that optimize efficiency and enhance product quality. One such technology that has transformed production processes across various industries is UV curing systems. These systems utilize ultraviolet (UV) light to initiate a photochemical reaction that instantly cures coatings, adhesives, and inks. In this blog, we’ll explore the numerous advantages of UV curing systems and their impact on modern manufacturing.

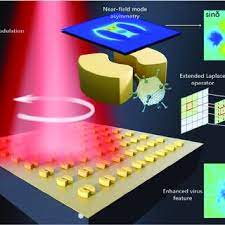

Understanding UV Curing Systems

UV curing systems consist of several key components, including a UV light source, a curing chamber, and specialized formulations known as UV-curable materials. When exposed to UV light, these materials undergo a rapid curing process, converting liquid coatings or adhesives into solid, durable products. Unlike traditional curing methods that rely on heat or air drying, UV curing offers significant advantages in terms of speed, precision, and energy efficiency.

Applications Across Industries

The versatility of UV curing systems makes them indispensable across a wide range of industries:

- Printing and Packaging: UV curing systems are commonly used in the printing industry for instant drying of inks and coatings on various substrates, resulting in vibrant colors and enhanced print quality.

- Electronics Manufacturing: In electronics manufacturing, UV curing systems play a crucial role in bonding and encapsulating electronic components, ensuring reliable adhesion and protection against environmental factors.

- Automotive: UV curing systems are employed in automotive manufacturing for bonding and sealing components, providing durable finishes that offer resistance to scratches and UV radiation.

- Medical Devices: UV curing systems are utilized in the medical industry for assembling and bonding medical devices and equipment, meeting stringent regulatory requirements for medical applications.

Advantages of UV Curing Systems

The adoption of UV curing systems offers numerous advantages to manufacturers:

- Faster Production Times: UV curing enables rapid curing times, leading to shorter production cycles and increased throughput.

- Enhanced Product Quality: UV-cured products exhibit superior properties, including enhanced durability, scratch resistance, and color consistency.

- Energy Efficiency: Compared to traditional curing methods, UV curing requires less energy and produces minimal heat, resulting in reduced energy consumption and lower operating costs.

- Environmental Benefits: UV curing eliminates the need for solvents and reduces volatile organic compound (VOC) emissions, contributing to a cleaner and safer working environment.